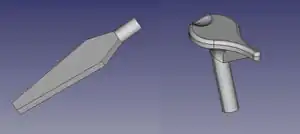

Seat

A bike seat is a simple, but necessary part of a bike that holds most of the weight of the biker. In many developing countries, biking is the most common mode of transport. Additionally, a mud flap is important for keeping the rider clean, especially during rainy seasons.

Bill of Materials

Tools needed

- MOST Delta RepRap or similar RepRap 3-D printer

- Depending on type of bike, an allen wrench or screw driver may be needed to attach seat.

Skills and knowledge needed

- General 3D printing knowledge is needed to make parts.

Technical Specifications and Assembly Instructions

- Recommended Print Settings: Temp=210, Material=PLA, Layer Height=0.3mm, Infill=25%

- Print Time Estimate: 4 hours 20 minutes

- Assembly Time Estimate: 15 minutes

Common Problems and Solutions

- A common problem is the tolerance for the assembly is too tight. To solve this, use a thicker wall thickness and use sandpaper to create a snug snap fit.

Cost savings

- If your solution is not a low cost one then it is not really appropriate.

Benefited Internet Communities

This article is issued from Appropedia. The text is licensed under Creative Commons - Attribution - Sharealike. Additional terms may apply for the media files.