Table Saw Fence Push Stick

Table Saw Fence Push Stick

Project developed by User:JasonBell

Abstract

This part solves the problem of making very thin cuts on a table saw in a safe way. All current push sticks or push blocks on the market do not allow for cuts under 1/2" while still maintaining the guards over the saw blade. This push stick rides on the fence of the saw and allows for a safer cut and makes smaller cuts possible without ruining the user's push stick.

Bill of Materials

This part can be fully printed and no other components are necessary.

Tools needed

- MOST Delta RepRap or similar RepRap 3-D printer

Skills and knowledge needed

Product is to be used on a table saw. Safe operation and knowledge of table saw needed for proper use.

Technical Specifications and Assembly Instructions

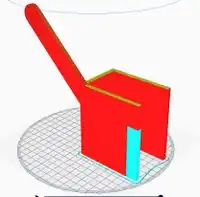

Orient STL in slicing software as seen below (supports shown):

If printer does not have vertical space required then orient like this(supports shown):

Push stick in use can be found below:

Printing / Slicing Settings

Temperature: 210C

Infill: 30% or more

Supports: Yes

Skirt: Yes

Speeds: First Layer: 40 mm/s, 70 mm/s remainder of print

Layer Height: 0.15 mm

Material: PLA

Common Problems and Solutions

Support locations may vary depending on print orientation. The supports should put themselves in the correct locations when enabled

Cost savings

Estimated Cost in PLA: $1.40

Commercial Equivalent: No standard equipment performs this specific task in this way. The closest representation is a generic push stick found here

Cheapest Commercial equivalent with less functionality for $10.19

3D Printed for $1.40

Cost Savings ~ $8.79 +

% Cost Savings ~ 86% Savings +

Benefited Internet Communities

References

Woodworking Catalogs

Wood Working Tool Designs