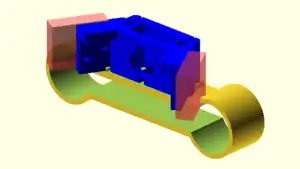

Vibration Dampener (MOST Delta: Athena)

This vibrational dampener was designed to reduce the vibrational noise of the MOST Delta - Athena during printing. This is achieved by reducing the motor-end contact area with the table / desk and provides a "spring" like action. Most notable differences will be seen on non-rigid tables / desks.

Design and Printing

Design

OpenSCAD was utilized for all modeling operations. The MOST-Athena GitHub file repository is located here. The motor-end assembly was imported into OpenSCAD and the part was designed to accommodate the geometrical constraints of the parts provided to MY4777.

Printing

The stiffness of the component is driven by the infill percentage. Adjust as necessary to achieve your desired characteristics.

Print Parameters Utilized:

- Layer Thickness: 0.2mm

- Skin Thickness: 1.0mm

- Top/Bottom Thickness: 0.5mm

- Temperature: 180C

- Speed: 80mm/s (60mm/s outer contour)

- Flow: 100%

- Infill: 50%

Installation

The model is designed to snap fit onto the bottom of the motors ends. Print out qty. 3 of the STL and install as shown below.

Placement. *Note: You may have to invert the printer to apply enough pressure.

Placement. *Note: You may have to invert the printer to apply enough pressure. Fully Installed.

Fully Installed.

Link to Files

The file repository is located on Thingiverse thing:1809228

Other Sound Dampening Techniques

- The default U,V,W motor acceleration is 4000mm/s. You can uniformly decrease this to any lesser value to quiet the quick movements of the motors / bearings.

- Utilizing a heavy weight grease on the guide rods seems to reduce the vibrations of the quick bearing movements.